From Cocoa to Chocolate

The great botanist Carl von Linné was by no means the first to recognize the unique qualities of the plant to which he gave the botanical name Theobroma Cacao L.. Theobroma means “food of the gods.” The Toltecs, Mayas, and Aztecs had already recognized cocoa as such, and it is from them that the name cacauatl has been handed down to us. As early as around the year 600, the Mayas in Central America were cultivating cocoa. They used the cocoa beans to prepare a highly nutritious drink, which they called Xocolatl — from which today’s word “chocolate” is likely derived.

The Spanish conquistadors of the 16th century also took an interest in cocoa. In 1528, Cortez brought the first cocoa and the utensils needed to prepare this exotic drink to Spain, where it soon became very popular at the royal court.

In 1615, the Infanta Anne of Austria, who had grown up in Madrid, introduced drinking chocolate to the French court as the wife of King Louis XIII. In Paris, it became a status symbol and fashionable drink of the aristocracy, and from there spread throughout Europe. While drinking chocolate lost importance in the 19th century, solid chocolate grew in popularity, with its beginnings in France in the years after 1830.

Aztecs preparing “Xocolatl”: cocoa beans are roasted, ground, and frothed with water and spices (Olfert Dapper, The Unknown New World).

Chocolate comes to Switzerland…

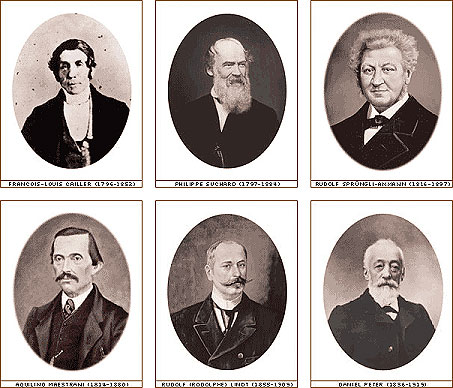

In 1819, François-Louis Cailler opened one of the first mechanized chocolate factories in Corsier near Vevey, thus establishing the oldest existing chocolate brand in Switzerland. This marked the arrival of chocolate in the country that would soon produce its greatest promoters and pioneers. Philippe Suchard opened a chocolate factory in Serrières in 1826. In the same year, Jacques Foulquier (predecessor of Jean-Samuel Favarger) followed in Geneva; Charles-Amédée Kohler in Lausanne in 1830; Rudolf Sprüngli in Zurich in 1845; Aquilino Maestrani in Lucerne in 1852, later in St. Gallen; Johann Georg Munz in Flawil in 1874; and Jean Tobler in Bern in 1899.

Daniel Peter founded a chocolate factory in Vevey in 1867. After many attempts, he succeeded in the seemingly obvious but technically difficult task of combining chocolate with milk, and thus, in 1875, invented milk chocolate. In 1879, Rodolphe Lindt opened a chocolate factory in Bern. With the process of “conching,” he succeeded in producing the world’s first melting or fondant chocolate.

In the years that followed, many other Swiss entrepreneurs founded companies whose success helped shape the soon worldwide reputation of Swiss chocolate.

The First Golden Age of Swiss Chocolate

The years between 1890 and 1920 were a true golden age for the Swiss chocolate industry. This coincided with the great era of Swiss tourism. Members of the upper classes from around the world, who spent their holidays in Switzerland, discovered and grew fond of Swiss chocolate and carried its reputation back to their home countries. Between 1900 and 1918, the production of pioneering Swiss chocolate makers conquered the world market. Up to three-quarters of Swiss chocolate was exported. Thus, little Switzerland became a global chocolate power. Of course, “Swiss chocolate” earned its worldwide reputation not only because of the quantity exported, but above all thanks to its quality, which surpassed the mass of chocolate produced in other countries.

Through Crises to a New Bloom

At the end of the 1920s, hard times began for the Swiss chocolate industry. Increased protectionism and the economic crises of the 1920s and 1930s led to the loss of export markets. The Second World War brought strict import restrictions on sugar and cocoa and, in 1943, rationing.

Since 1950, the Swiss chocolate industry has enjoyed steady development. Automation and new technologies for chocolate production advanced. Ongoing economic integration and the global reduction of tariffs fostered international trade. Manufacturers recognized the signs of the times and continued to expand their market positions in many countries around the world.

The development of innovative products and formats that meet modern consumer habits, the upholding of high quality, the consistent modernization of production facilities, and the promotion of professional training for employees are the means by which the Swiss chocolate industry is able to maintain its global standing well into the 21st century.

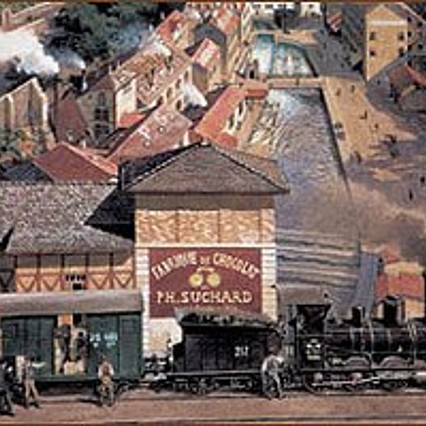

Soon, the first manufactories grew into real factories. By the end of the 19th century, the largest was that of Philippe Suchard in Serrières.

Where women once carefully placed pralines into boxes at long tables and later on conveyor belts, robots now perform the same task in a fraction of the time previously required. Attentive employees monitor and correct the robots’ work.

The oldest method of molding: the fragrant, liquid chocolate mass is poured into shallow molds that represent the negative shape of the finished product.

The Cocoa

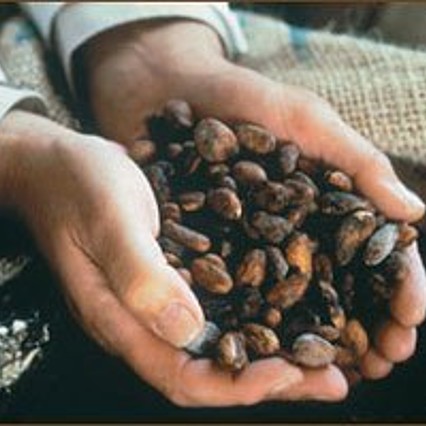

The beans, once removed from the pod, are heaped together, covered, and left to ferment. During this process, the beans lose their ability to germinate while at the same time developing part of their aroma. After drying, the cocoa beans are ready for shipment. They are purchased by processing companies at the international cocoa exchanges in London and New York.

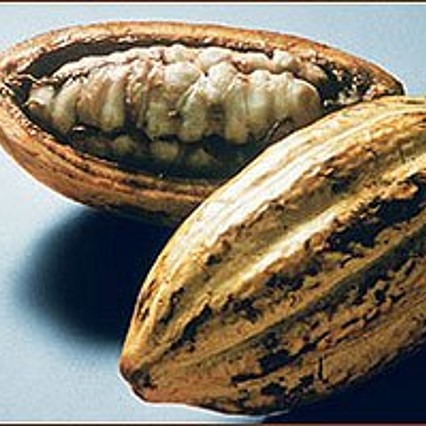

Cocoa is a particularly noble product of the tropics. The cocoa tree thrives in tropical regions north and south of the equator. Its fruits, which grow directly on the trunk, are harvested twice a year and contain 20 to 30 white cocoa beans each.

Cocoa fruit with the still whitish cocoa beans.

The fermented and dried cocoa beans as they are delivered to the factories.

How Chocolate is Made

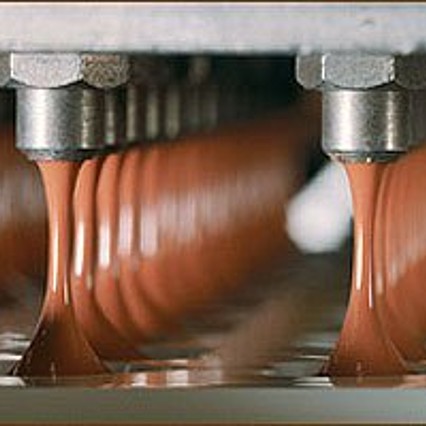

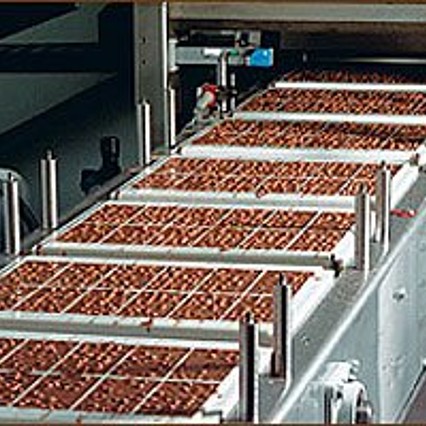

Chocolate production is based on the traditional craft of the confectioner and chocolatier. Even today, industrial production still follows the original artisanal steps, but at every stage highly advanced technical equipment has taken over the execution. This not only makes it possible to streamline production but above all guarantees consistently high quality. Cocoa beans are the most important raw material for chocolate making. After a thorough intake and quality check, the raw cocoa is carefully cleaned, broken, roasted, and ground. The resulting cocoa mass, when mixed with sugar and additional cocoa butter, forms the base for classic dark chocolate. If milk powder or condensed milk is added, it becomes the base for milk chocolate. White chocolate, on the other hand, contains no brown cocoa mass. These three basic mixtures are the starting point for all chocolate varieties. After mixing, the bases are ground very finely and refined through conching. In this way, cocoa mass becomes chocolate mass, which is then ready to be formed into solid or filled bars — with nuts, almonds, fruits, or liqueur — pralines, and many other specialties.

Finally, the delicate large and small chocolates are packed into wrappers, boxes, and bonbonnières, and ultimately into large shipping cartons before reaching the trade’s intermediate storage facilities and being exported worldwide.

A look into a chocolate bar production line. The molds are filled and shaken to remove air bubbles before they enter the cooling tunnel.

Qualität

Connoisseurs recognize the quality of a chocolate when they break off a piece: the break is firm and crisp, the edges are clean, and the surfaces do not crumble. The nose also detects quality: the aroma of fine chocolate is full and rounded, yet never overpowering. On the tongue it becomes unmistakable: good chocolate melts “smooth as butter,” neither sticking unpleasantly to the palate nor feeling grainy, and it leaves no aftertaste. Its flavor is fine, delicate, perfect — unique.

Connoisseurs recognize quality when they break off a piece from a fine chocolate bar: the break is firm and crisp, the edges are clean, and the surfaces do not crumble.

Haltbarkeit

Depending on the recipe, chocolate has a shelf life of up to 12 months, and dark chocolate even up to 15 months. Chocolate should be stored at a temperature between 10° and 18°C, protected from light and moisture.

Chocolate is healthy! Rarely does a food contain, in such a small space, such a large concentration of valuable and energy-providing nutrients such as proteins, carbohydrates, trace elements, minerals, and vitamins — all derived from nature.

The usable energy of a 100 g bar of milk chocolate amounts to about 2300 kilojoules or 550 kilocalories. Chocolate is good and healthy. It supports the always desirable balanced diet — but does not replace it.

(Source: Chocosuisse Schweiz)

Many confectioners still create their own chocolate products with great skill and dedication, thereby making an important contribution to the reputation of Swiss chocolate. They usually source the chocolate mass in the form of so-called couverture from specialized companies or large chocolate factories.

Swiss Chocolate

The Swiss chocolate industry is renowned worldwide for its high quality, which is ensured through premium raw materials, modern production methods, and strict quality standards. Swiss chocolate must be produced entirely in Switzerland from cocoa beans, sugar, and, where applicable, milk. Any production carried out abroad must be clearly declared on the packaging. CHOCOSUISSE actively works against the misuse of the term “Swiss chocolate.”

Chocolate production in Switzerland is strictly regulated. Since 1995, up to five percent of other vegetable fats besides cocoa butter may be used without falling below the minimum cocoa content. This regulation mainly helps with exports to warmer countries but has not been used by Swiss manufacturers to date.

Swiss Chocolate Consumption

The highly detailed sales statistics of the Swiss chocolate industry differentiate between various product categories (bars, chocolate confectionery such as pralines, semi-finished products, etc.). These categories include dark, white, and milk chocolate. The exact shares of the different types can only be estimated. Milk chocolate accounts for just over 80% of total chocolate consumption in Switzerland. Dark chocolate makes up around 10–15%, while white chocolate represents 4–5%. These proportions shift in line with changing consumer habits. Currently, there is a trend toward more dark chocolate.

In 2023, approximately 97,017 tons of chocolate products (excluding cocoa and chocolate powders) were consumed in Switzerland. This corresponds to an average per capita consumption of 10.9 kg, putting Switzerland at the top of all consuming countries. However, it should be noted that purchases made by holiday visitors and cross-border commuters are included in these figures, though their exact quantities are not known.